Are you considering installing engineered wood flooring in your home but unsure about the underlayment? This article will guide you through everything you need to know about underlay for engineered wood flooring.

Learn about the purpose of underlayment, different types like cork, foam, rubber, and felt, and choose the best wood flooring underlayment options for your needs. Discover key factors to consider, installation tips, and maintenance tricks to ensure your flooring stays in top condition.

What is Engineered Wood Flooring?

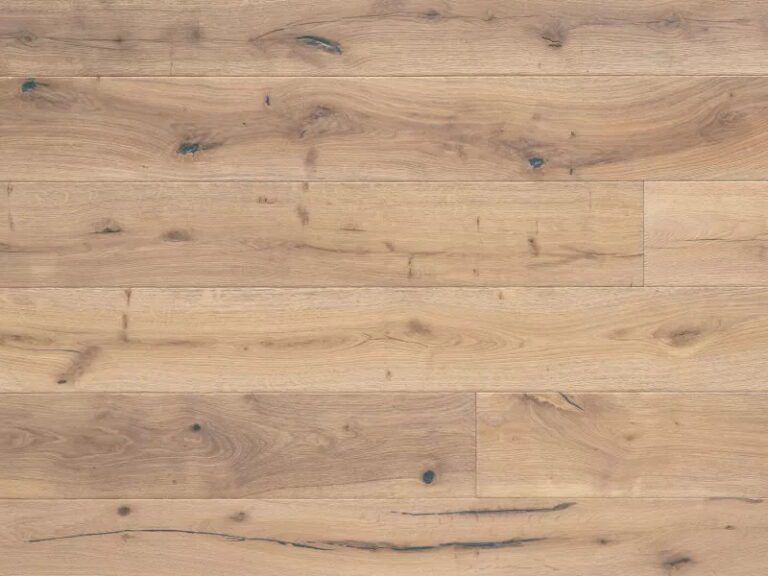

Engineered wood flooring is a type of flooring that consists of real wood veneer adhered to multiple layers of wood or plywood. It provides the look and feel of solid hardwood with added stability.

With engineered wood flooring, the top layer, known as the ‘wear layer,’ is crafted from high-quality hardwood, providing the authentic appearance of solid wood. Beneath this veneer, the strong layers of wood or plywood are cross-layered for increased resistance to moisture and temperature changes, making it an ideal flooring choice for various rooms in a home.

Engineered wood flooring offers exceptional durability, being less prone to warping and bowing compared to solid hardwood floors. Its construction minimizes the expansion and contraction that can occur with traditional hardwood, enhancing its dimensional stability.

See product: Elka 13.5mm Real Wood Rustic UV Lacquered Oak

What Is Underlayment for Engineered Wood Flooring?

Underlay for engineered wood flooring is a crucial layer installed between the subfloor and the engineered wood planks. It acts as a buffer to provide additional support and protection.

One of the key roles of underlay is soundproofing, as it helps reduce noise transmission between floors, creating a quieter and more peaceful environment in the living space. Underlay serves as a barrier against moisture, preventing any potential damage that could occur due to water exposure. It aids in subfloor levelling, ensuring a smooth surface for the engineered wood flooring installation, which ultimately enhances the overall aesthetics of the room.

What Is the Purpose of Underlayment?

Does engineered wood flooring need underlay? The primary purpose of underlay for engineered wood flooring is to provide cushioning, sound insulation, and moisture protection. It also helps in smoothing out minor imperfections in the subfloor.

Engineered wood flooring underlay plays a crucial role in enhancing the overall comfort of a space by adding a soft layer between the hard subfloor and the wood planks, making walking barefoot or standing for long periods more enjoyable.

The sound insulation properties of the underlay reduce the noise transmitted between floors, creating a quieter and more peaceful environment within the home.

Efficient moisture protection provided by the underlay helps prevent damage to the wood flooring caused by dampness or spills, thus extending the longevity of the floor.

Factors to Consider when Choosing Underlayment for Engineered Wood Flooring

Do you need underlay for engineered wood flooring? When selecting underlay for engineered wood flooring, it is essential to consider factors such as moisture resistance, sound absorption, thermal insulation, and compatibility with the specific type of flooring.

One of the primary considerations is moisture resistance, as moisture can damage both the flooring and the subfloor. Choose an underlay that has a vapour barrier or moisture-blocking properties to protect your engineered wood flooring.

Sound absorption is another crucial factor to keep in mind. Look for underlay options that offer sound reduction qualities to minimise the impact of footsteps and other noises, especially in multi-storey buildings.

Thermal insulation can contribute to energy efficiency in your space. Select underlay with good insulating properties to help regulate indoor temperatures and reduce heating costs.

a. Moisture Resistance

Moisture resistance is a critical factor to consider when selecting underlayment for hardwood floors, as excess moisture can lead to warping and damage.

Proper moisture resistance in underlayment acts as a barrier against water infiltration, preventing potential issues such as mould growth and decay in the hardwood flooring. Without adequate protection, moisture can seep through the underlayment, causing irreversible damage to the floorboards.

By choosing underlayment with high moisture resistance qualities, homeowners can ensure the longevity and durability of their hardwood floors. This safeguard shields the flooring from various moisture-related problems, ultimately preserving its aesthetic appeal and structural integrity.

b. Sound Absorption

Sound absorption properties of underlay play a crucial role in reducing noise transmission and creating a quieter indoor environment for hardwood floors.

Soundproofing underlay acts as a barrier against impact noise, such as footsteps and furniture movement, which helps in maintaining peaceful living or working spaces. This is particularly valuable in homes, offices, or flats where privacy and tranquillity are paramount. By minimising sound transfer between floors, underlay contributes to a more harmonious atmosphere, allowing individuals to focus, relax, or sleep without disturbances. Its ability to dampen impact noise ensures that activities in one room do not disrupt those in adjacent spaces, fostering a sense of privacy and comfort.

c. Thermal Insulation

Thermal insulation provided by underlay contributes to maintaining a comfortable indoor temperature, especially in conjunction with underfloor heating systems, while also helping to reduce heat loss through joints.

One of the significant advantages of thermal underlay lies in its ability to act as a barrier against cold floors, thereby creating a cosy environment. This underlay serves as a safeguard, ensuring that the heat produced is retained within the room, rather than escaping through the floor. The insulation properties of thermal underlay play a crucial role in reducing energy consumption, as less energy is needed to maintain the desired temperature levels. In addition, the well-designed joints in thermal underlay further enhance its efficiency by preventing air leaks and heat transfer, ultimately leading to improved energy efficiency and cost savings.

d. Compatibility with Flooring Type

Choosing underlay that is compatible with the specific type of wood flooring is essential to ensure proper installation and optimal performance.

- When the underlay and wood flooring align harmoniously, it creates a sturdy foundation that enhances the structural integrity of the floor, reducing the risk of issues such as buckling or squeaking over time. Compatibility between the two materials also helps in sound absorption, providing a quieter and more comfortable environment.

- Along with stability, the right underlay can improve the insulation properties of the floor, aiding in energy efficiency and maintaining a comfortable indoor temperature. It acts as a protective barrier, shielding the wood from moisture and minimising the impact of subfloor imperfections.

Best Types of Wood Floor Underlayment

What type of underlay for engineered flooring? The best underlay for engineered wood flooring depends on factors such as moisture levels, sound insulation needs, and personal preferences. Popular options include cork underlay, foam underlay, rubber underlay, and felt underlay.

When considering underlays for engineered wood flooring, cork underlay stands out for its natural moisture resistance and ability to provide thermal insulation, making it an excellent choice for areas prone to dampness. On the other hand, foam underlay is highly versatile, offering cushioning underfoot and sound-absorbing properties, perfect for reducing noise transmission between floors.

Rubber underlay excels in impact resistance, durability, and eco-friendly characteristics, making it ideal for high-traffic areas and environmentally-conscious homeowners. Meanwhile, felt underlay is valued for its affordability, easy installation, and ability to level minor subfloor imperfections, making it a budget-friendly yet effective option.

1. Cork Underlayment

Cork underlay is a popular choice for engineered wood flooring due to its natural moisture-resistant properties, sound absorption capabilities, and environmental sustainability.

One of the standout benefits of cork underlay is its inherent moisture resistance, making it ideal for areas prone to dampness or humidity. This feature not only protects the wood flooring above it but also ensures durability and longevity.

The acoustic insulation properties of cork underlay contribute to creating a quieter and more peaceful indoor environment by reducing impact noise and footfall sound. Being an eco-friendly material, cork underlay is harvested from the renewable bark of cork oak trees without harming the tree itself, making it a sustainable choice for environmentally-conscious consumers.

2. Foam Underlayment

Foam underlay is known for its lightweight construction, ease of installation, and excellent sound-dampening properties, making it a popular choice for engineered wood flooring installations.

Its lightweight nature allows for easy handling and manoeuvrability during the installation process, reducing strain on the installer. The sound-dampening properties of foam underlay create a quieter indoor environment by absorbing impact and reducing noise transmission, which is especially beneficial in multi-storey buildings or areas with high foot traffic.

Foam underlay provides a level of cushioning that helps protect engineered wood floors from damage caused by subfloor imperfections or minor movements. This added support can prolong the lifespan of the flooring and enhance comfort underfoot.

3. Rubber Underlayment

Rubber underlay offers exceptional shock absorption, moisture resistance, and durability, making it a reliable choice for engineered wood flooring in high-traffic areas or where impact protection is crucial.

Its remarkable ability to absorb impact helps in reducing noise and minimising damage to the floor structure, ensuring a peaceful environment and prolonging the lifespan of the wood flooring.

The moisture resistance properties of rubber underlay prevent water damage, mould growth, and warping of the wood, maintaining the integrity of the flooring in damp or humid spaces.

When installed in areas with heavy foot traffic, the longevity of rubber underlay shines through, as it withstands constant pressure and maintains its supportive qualities over time.

4. Felt Underlayment

Felt underlay provides a soft and comfortable feel underfoot, along with excellent thermal insulation and moisture protection, making it an ideal choice for engineered wood flooring in domestic settings.

The cushioning effect of felt underlay helps to reduce noise transmission, creating a quieter indoor environment. Its resilience allows it to adapt to uneven subfloors, ensuring a smooth finish for the wood flooring installation. The breathable nature of felt underlay prevents the accumulation of mould and mildew, enhancing indoor air quality and overall health.

How to Install Underlayment for Engineered Wood Flooring

The installation of underlayment for engineered wood flooring involves cleaning the subfloor, laying out the underlayment material, and securing it in place before installing the engineered wood planks over the prepared surface.

Before beginning the underlayment installation, ensure the subfloor is clean, dry, and level. Remove any debris, nails, or staples that could affect the underlayment’s flatness.

Once the subfloor is prepped, roll out the underlayment material in the direction of the longest wall. Trim any excess material using a utility knife so that it fits snugly against the walls.

Overlap the seams of the underlayment sheets by at least 6 inches and tape them securely using underlayment tape to prevent moisture from seeping through.

Tips for Maintaining Underlayment and Engineered Wood Flooring

To maintain underlayment and engineered wood flooring, it is essential to keep the floors clean and dry, avoid excessive moisture exposure, and address any damage promptly to ensure the longevity and performance of the flooring system.

Regularly vacuuming or sweeping the floors to remove dirt and debris can prevent scratches and maintain the floor’s aesthetic appeal. Using a damp mop with a mild cleaning solution specifically designed for engineered wood flooring can effectively remove stains without causing damage.

It is crucial to monitor the humidity levels in the room to prevent swelling or warping of the wood. Consider using a dehumidifier in areas prone to high moisture levels.

Should any damage occur, such as scratches or dents, consider using wood filler or contacting a professional for repair services to ensure the integrity of the flooring.

Looking to choose underlay for your flooring? Trust TEKA Flooring for this. We provide flooring accessories, including underlay from Ball & Young, a distinguished underlay company that has been providing exceptional flooring solutions with a commitment to quality and innovation.

We also offer other accessories that can help enhance the aesthetics of your home, such as wall-paneling from Tekpanel. Go to our showroom in Peterborough and get the exclusive in-store discount, full collection products, and free expert advice!

Read Also: